Polyvinyl Chloride

CAS Number: 9002-86-2

English Abbreviation: PVC

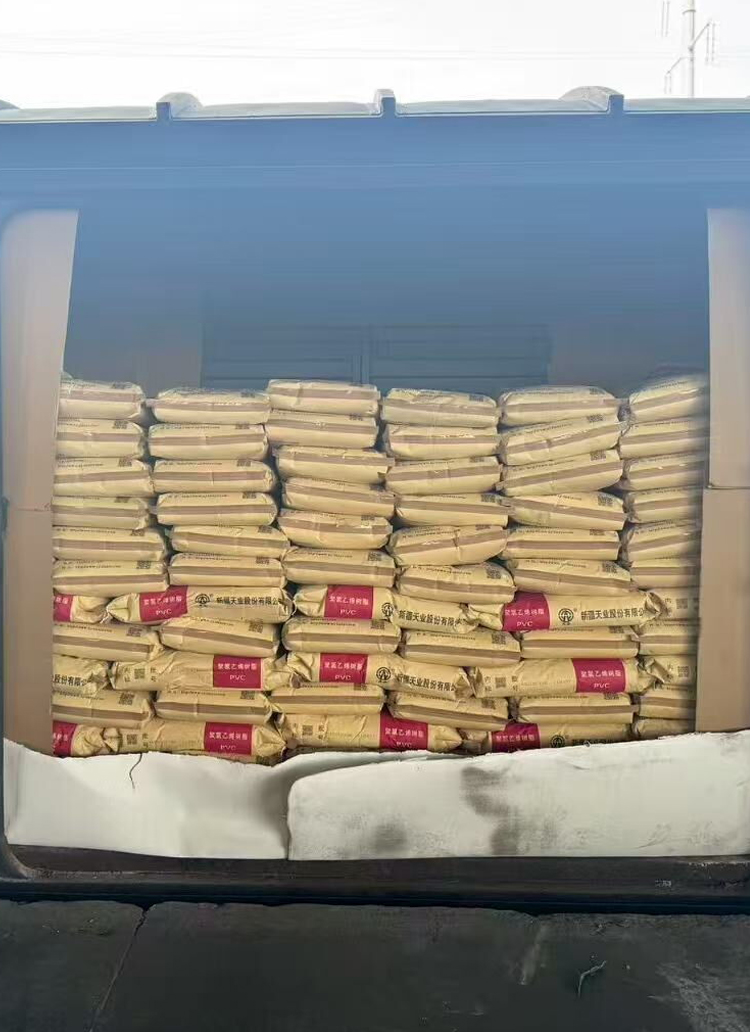

Pack Size:

25KG/Bag, 800KG/Bag, 1000KG/Bag, 1200KG/Bag

Storage:

Store closed containers in a cool, dry,well-ventilated area.

Avoid exposure to direct sunlight.

Main Characteristics

- ● Favorable price and high quality

- ● Insulating, moisture-proof, oil-resistant, acid-resistant, and alkali-resitant properties

Main Brands and Types

| Brands | Types |

| Xinfa | SG-5 |

| Erdos | SG-5 |

| Sanlian | SG-5 |

| HWASU | SG-5 |

| Jinyuyuan | SG-3/SG-5 |

| Dezhou Shihua | SG-7/SG-8 |

| Jiahua | JH-1000 |

| Tianye | SG-3/SG-5/SG-8 |

| Zhongtai | SG-3/SG-5/SG-8/MG-8/(SG-5 suspension special PVC resin for soft products) |

| Other Brands | Please contact us for details |

Applications

- ● SG-3 (S-1300) is used in producing electrical insulating materials, agricultural film, daily-use plastic products.

- ● SG-5 (S-1000) is used in producing transparent products section bar, hard tube and decorative materials.

- ● SG-7 (S-800) , SG-8 (S-700) is used in producing clear foil, hard injection molding.

Description

Polyvinyl chloride is high molecular compounds polymerized by vinyl chloride monomer(VCM) with structural element as CH2-CHCLn,degree of polymerization usually as 590-1500. In the process of re-polymerization, affected by kinds of factors such as the polymerization process, reaction conditions, reactant composition, additives etc. It can produce eight different types of PVC resin performance is different. According to residual content of vinyl chloride in polyvinyl chloride resin, is can be divided into: commercial grade, food hygiene grade and medical application grade in appearance, polyvinyl chloride resin is white powder or pellet.

We offer many types of polyvinyl chloride, which can be widely used in the production of various plastic products, including hard products such as plates, pipes, pipe fittings and profiles, as well as soft products such as films, artificial leather, plastic shoes, cable materials and foam materials. It has extensive applications in industry, agriculture, construction, daily necessities, packaging and power, etc.

Specifications

| Items | SG3 | SG5 | SG7 | SG8 | J-1000 |

| Average Degree of Polymerization | 1350-1250 | 1080-980 | 850-750 | 750-650 | 1135-981 |

| K Value | 71-72 | 66-68 | 60-62 | 55-59 | 65-67 |

| Viscosity, ml/g | 135-127 | 118-107 | 95-87 | 86-73 | 118-107 |

| Foreign Particle | 16max | 16max | 16max | 16max | 8max |

| Volatile Matter (including water) Content, % | 0.30max | 0.40max | 0.40max | 0.40max | 0.20max |

| Apparent Density, g/ml | 0.45min | 0.45min | 0.52min | 0.52min | 0.50min |

| 0.25mm Sieve Retained, % | 1.6max | 1.6max | 1.6max | 1.6max | 1.6max |

| 0.063mm Sieve Retained, % | 97min | 97min | 97min | 97min | 97min |

| No.of Grain/400cm2 | 20max | 20max | 30max | 30max | 6max |

| Plasticizer Absorption of 100g Resin, g | 26min | 19min | 12min | 12min | 22min |

| Whiteness Degree 160℃10min, % | 78min | 78min | 75min | 75min | 80min |

| Residual Chlorethylene Content, mg/kg | 5max | 5max | 5max | 5max | 2max |